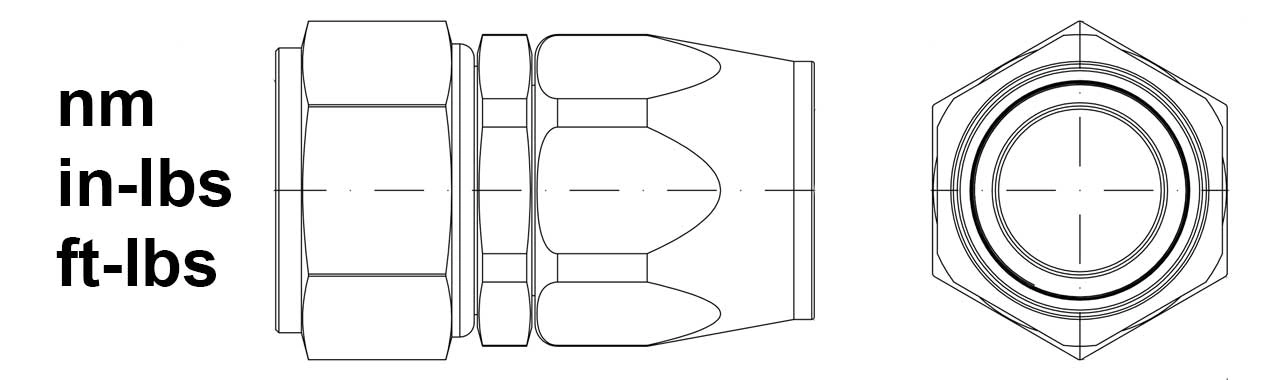

AN fittings: Tightening torque

To know how tight an AN fitting should sit, you need a special torque wrench. But it is also possible to tighten with regular hand tools by hand with some previous experience. This is actually how it's done and have been leak-free over years despite varying tightening torques where the fittings has been tighten by "feel". There are a few things to keep in mind if you want to do this correctly with torque.

- Tightening torque AN-hose ends

- Tightening torque AN-hose

Tightening torque AN-fittings

Correct AN hose end tightening torque can be found here.

AN4 - 16nm

AN6 - 22nm

AN8 - 39nm

AN10 - 49nm

AN12 - 62nm

AN16 - 94nm

AN20 - 115nm

This can first be threaded by hand until it stops, then tighten with tools.

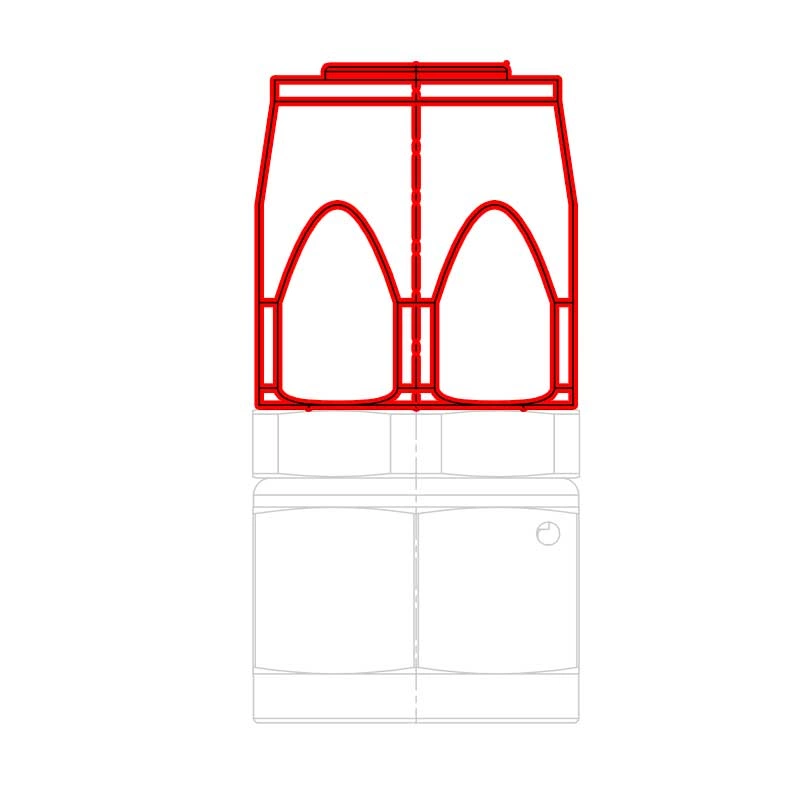

Tightening torque AN-hose

The tightening torque for AN hose is when you tighten the part that is mounted against a hose, the part without a thread. These elements only apply to AN fittings in aluminum, not pipe or other fittings.

For best results, if using a special torque wrench, tighten to the lower part of the torque range. If it leaks, tighten it until the leak ceases (without exceeding the maximum torque). Lubricate the threads and sealing surfaces lightly with oil before mounting as you want to avoid dry mounting whenever possible.

AN4 - 8,3-11,66ft-lb - 11,25-15,8nm

AN6 - 12,5-16,25ft-lb - 16,9-22,0nm

AN8 - 22,5-29,0ft-lb - 30,5-39,0nm

AN10 - 30-36ft-lb - 40,0-48,8nm

AN12 - 38-46ft-lb - 51,5-62,0nm

AN16 - 58-70ft-lb - 78,6-94,9nm

AN20 -71-85ft-lb - 96,2-115nm

Most people do not use tightening torques when tightening AN fittings, they tighten the connections by hand without torque tools, just like a hose clamp.