Exhaust Gas Temperature Sensor (EGT Sensor)

Information about EGT (Exhaust Gas Temperature) sensors. These are also known as exhaust temperature sensors.

- Information about EGT Sensors

- Different Types

- Choosing a Sensor

- Connections

- Materials

- Installation

- Settings in the ECU

- Accessories

- Troubleshooting

- Problems

- Compare EGT Sensors

1 ▼

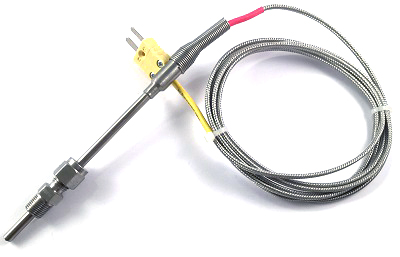

Information about EGT Sensors

Exhaust Gas Temperature Sensor, or EGT Sensor as it is also called, is used to measure the exhaust temperature in the exhaust manifold and front exhaust system/downpipe. These sensors facilitate mapping to achieve the best results for maximum power.Since it is common to install one sensor per cylinder, you can easily monitor that the combustion is correct in the cylinders, and the control system can be programmed to adjust and rectify issues in case of excessively high exhaust temperatures. Modern control systems can also compensate individually per cylinder if needed.

Type K exhaust temperature sensors measure temperatures from approximately -100 to 1300 degrees Celsius.

2 ▼

Different Types

There are both straight and angled sensors to provide you with the best option to fit your specific setup. The length of the cable also varies by manufacturer. This cable can be shortened, and the connector can be re-pinned or screwed on.

When it comes to the measurement part of the sensor, there are two variants: one with an open measurement area and one with a covered measurement area.

The open measurement area is faster but more sensitive to temperature than the one with a covered tip. The covered tip/measurement area holds up better but is not as fast.

3 ▼

Choosing a Sensor

The most common type of EGT sensor is Type K. Type N is also present but nearly all usage is of Type K. It is also Type K sensors that are available in the market.

For these sensors to function, mini Type K connectors are required, and your control system must be able to handle EGT sensors.

4 ▼

Connections

Clamp Connection

Used to attach the sensor to the exhaust manifold. This consists of 3 parts: a lower section with the threads that attach to the manifold, a clamp connection/olive, and a nut that tightens onto the clamp connection.

Weld Nipple

Used to screw down the clamp connection that holds the sensor in place. This is typically available in 1/8", which is the most common size. A 1/4" NPT is also available but is less common. In the original market, where an exhaust temperature sensor is mounted, other threads like M14 are often found. These are commonly associated with diesel particulate filters (DPF).

EGT Amplifier

Measures approximately 0-1250°C (TYPE-K) and outputs a 0-5V signal. It works with all control systems that can accept a 0-5V signal for sensors.

Type K Connector

This is the standard in the aftermarket for racing.

5 ▼

Materials

An exhaust temperature sensor is made of various materials depending on the manufacturer, but aside from the outer shell, there is a measurement element inside the sensor that is surrounded by a type of ceramic. This makes the sensor sensitive to impacts and strong vibrations. However, it is fine to mount these directly in the exhaust system. That said, this is a serviceable part that will need to be replaced eventually.

In motorsport, the tube that the measurement element is in is often protected with Inconel to withstand higher temperatures for a longer time.

6 ▼

Installation

The exhaust manifold must have an outlet for the EGT sensor; these can be threaded, or a nipple with threads can be welded in place. The most common size is, as mentioned, 1/8" NPT. Installation can be done with one sensor per cylinder directly after the exhaust flange or with a single sensor mounted in the collector.

When installing, it is important not to tighten too hard, as the threads can strip—especially if made of stainless steel. Before tightening the clamp connection, ensure that the top of the sensor protrudes halfway into the pipe. This serves as a reference point but can vary depending on the tuning.

Even though the wiring can withstand certain temperatures, it should be routed away from the heat and ideally further protected with a heat sleeve. In a serious installation, a heat shield plate can even be installed between the exhaust manifold and nearby components that are sensitive to heat.

The wiring should be mounted securely away from moving parts. An EGT sensor cannot be used with standard analog or digital inputs but must have a dedicated built-in or external amplifier for this type of sensor.

Connection of EGT Amplifier:

Ground to ECU

Signal to ECU (0-5V)

Ground to chassis

+12V ignition voltage

Connection of EGT:

Ground to ECU

Signal to ECU (0-5V)

Do not tighten a tapered thread too hard—this can strip it, especially if it is stainless steel.

7 ▼

Settings in the ECU

The most common exhaust temperature sensor in the aftermarket is Type K, which is often preset in the control system. Type N, among others, is also available. EGT is an important part of engine safety. High exhaust temperatures—especially on one cylinder—can be quickly detected and adjusted in the control system to prevent engine damage.

Depending on the control system, there may be several different settings. We mention a few here.

Filtering of Sensor

If a sensor is not measuring correctly, an internal filter can be applied to that channel.

Error Checking

Internal checking for sensor errors is a good feature to have as it helps protect the engine. However, if a sensor fails or behaves abnormally, you want a backup. In this case, it is labeled "sensor error." This function sets an error code and alerts you if something is not right.

Calibration

If a sensor's expected values do not match the installer's expected values, it can be calibrated in the control system. An offset of a few or several degrees can be made to fine-tune it. Remember that the sensor may struggle to measure the exact temperature, as it can vary by 100 degrees from one second to the next, and the response time is not very fast.

Fuel Adjustment

Fuel and many other parameters can be adjusted against EGT. If a cylinder runs hot, fuel can be added to that cylinder. If a cylinder experiences temperature spikes, safe mode can be activated to prevent any engine parts from breaking. There are many situations that can be included as safety measures.

8 ▼

Accessories

Heat Shield

A heat sleeve or heat shield that protects the wiring from the radiant heat of the exhaust manifold is essential for extending the lifespan of the sensor. Wrapping the exhaust manifold in exhaust wrap may make the most difference.

Connector

The connector that is installed is a male mini-K. The corresponding mini-K female connector is available as an accessory if it is not already installed on the wiring harness to the ECU.

Clamp Connection

The clamp connection includes an olive that secures the sensor. If this is lost, in many cases, a complete clamp connection that fits the specific sensor must be purchased.

Weld Nipple

To secure the sensor/clamp connection to the exhaust manifold, a nipple with 1/8" NPT threads is welded on. These are available in both steel and stainless steel. The exhaust manifold can also be drilled and threaded directly.

9 ▼

Troubleshooting

To easily troubleshoot a faulty sensor, you can remove the sensor from the exhaust manifold and manually heat the sensor to see if it registers in the control system. If you receive no reading, try using another sensor (that you know works) on the same channel. If you get a reading, the original sensor is defective. If you still do not get a reading, try the sensor on another channel in the control system. If you then get a reading, there may be a cable break or an issue with the control unit.

If you have access to it, external Type K measuring instruments can also help you determine whether the sensor is broken or not.

10 ▼

Problems

Some of the most common problems with exhaust temperature sensors.

- High temperatures for extended periods

- Impacts or strong vibrations

- Melted wiring due to heat

- Reversed connector

- Bent sensor body (ceramic detaches)

- Damaged sensor tip

▼

▼

-

Engine management / Electric

- Engine control system: The various parts available

- Ignition System Information

- Install motor control

- Pressure sensor - Information

- Temperature sensor - Information

- Buttons - Switches - Information

- Connectors - Information

- Cooling fan car - Information

- Exhaust gas temperature sensor - EGT Sensor

- Lambda sensor - Wide band lambda

- Relay - Information

- Relay box - Fuse central

- CAN protocol - Canbus

- Ethanol sensor - Information

- Gauges and Dash

- Trigger sensor information

- Dimensioning of cable [and fuse size]

- Distributor Problems (And Solution)

- How does an Ignition Coil work?