ECU software settings

- Engine configuration

- Fuel

- Ignition

- Inputs

- Outputs

- Variable Valve Timing (VVT)

- Tuning

1 ▼

Engine configuration

After installing the wiring harness conntct your computer to the ECU software:

Engine configuration and overall ECU settings is the first thing to do. The wrong settings will keep the engine from starting.

2 ▼

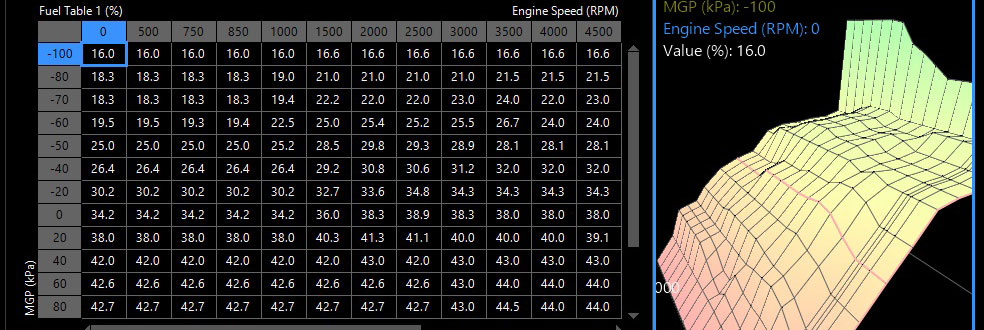

Fuel

asdfbgnhgbv

Pre defined fuel table are set to Lambda 1. To make engine operation smoother it can be set just under Lambda 1 (0,95-1)

This may need to be compensated in the engine management on N/A engines.

Example: When driving below 80km/h, a slight vacuum could result in the engine running too rich. However, around 90km/h, the pressure inside the scoop balances with the atmospheric pressure, ensuring proper fuel delivery. On the other hand, driving above 100km/h may create positive pressure in the air scoop, causing the engine to run too lean.

A small increase in inlet pressure of a supercharged engine can result in a significant boost in manifold pressure.

Locate at what speed the engine goes from running rich to lean at different throttle positions.

3 ▼

Ignition

4 ▼

Inputs

Ramlageröverfall, överfall till vevstakar och överfall i allmänhet får ej vridas, snurras, bytas eller på något sätt monteras annorlunda mot hur det satt original. Då kommer det inte att fungera pga. att varje överfall är unikt parat med sin plats.

5 ▼

Outputs

Input to output flowchart looks like this:

Input -> User software settings -> Output

- ECU outputs are connected to the parts you want to control, such as injectors or a cooling fan.

- ECU outputs can be reliant on ECU inputs such as sensors.

- The ECU software can be controlled to make output actions based on one or several input values.

- The output signal can also be "mapped", where both input values and the manually adjusted table within the software are considered before sending a signal on the output.

6 ▼

Variable Valve Timing (VVT)

Dual overhead cam (DOHC) valvetrain can take advantage of different types of variable valve timing (VVT) systems to make more power, driveability and fuel economy. Adjustments can be made on both the intake and exhaust side to allowi independent valve timing.

VVT Hardware

Fixed cam modes - The timing is controlled with solenoids by oil pressure and have two or three static profiles / timing.

Variable cam modes - Continious valve timing is where the valve timing is adjusting in real time to achieve the best performance.

Software

To take advantage of the variable valve timing you control the solenoid operation in the ECU software.

Fixed cam modes -

Variable cam modes -

NOTERA! Om större lagerspel på ramlager används så är det extra viktigt att verkligen kontrollera så olja verkligen kommer ut ordentligt till vevstakarnas vevtappar. vanligt är att oljan blir för varm = tunn och sedan rymmer ut ännu mer från ramlager med resultatet att vevlager skär.

7 ▼

Tuning

▼

▼

-

Engine and tuning

- Crankcase ventilation Information

- Engine block: Parts and how they fit together

- Engine deck clearance

- Head gasket - Information

- Engine bearing installation

- Engine bearing Information

- Blow off valve: Information and assembly

- Electronic Throttle Housing - DBW Information

- Noise from engine - Troubleshooting

- ARP bolts: Material and specifications

- Assembly of connecting rods

- Automotive cooling system problem

- Engine cooling system [How does it work?]

- Engine Oil system

- Engine water pump

- Exhaust pipe: Which material should you choose? [+extra information]

- Exhaust system: Parts and assembly

- Exhaust values - Information

- Exhaust wrap

- Intercooler guide

- Oil cooler - Information and FAQ

- Piston ring installation TIPS

- What do notes on Wiseco & JE pistons mean?